Overview

The negative impact on health and the environment that conventional plastics generate continues to pose a problem that Innovative Bottles is dedicated to reverse by having created a sustainable solution that eliminates those detrimental factors and empower our Eco System.

The result was a bio-resin based material that:

- Uses 42% Less energy in production than plastic

- Creates 32% Less Greenhouse Gases than plastic

- Results in a Sustainable End of Product Life Cycle (Zero Waste)

- Utilizes all the benefits of Polyactic Acid

- Is non-toxic, is 100% made from plants, is completely biodegradable (compost in three to six months

- Deteriorates faster than orange peels!

Focus

We have depended on plastic for generations and now we are drowning in it. This “miracle” material has made modern life possible but more than forty percent of it is used just once and the resulting waste is choking our oceans, wildlife, fisheries, and the environment as a whole. It is estimated that by the year 2050 we will have more plastic in the ocean than fish unless we all do something to reverse this destructive trend.

The single use medical industry usage is especially significant and hospitals in the U.S. alone produce more than 5.9 million tons of waste annually with more than half attributed to plastic products. While the vision and engineering road map of Innovative Bottles is to apply our patented Intellectual Property to other consumables, our first step is to solve the problem of the medical industry associated with single use medical devices and vials.

We share an interesting perspective that if plastic had been invented when the Pilgrims sailed from Plymouth, England to North America equipped with water bottles and plastic wrapped food their plastic waste would still be around four centuries later!

Why Bio-Resins?

It was vital that the raw materials we used to produce our products met three essential criteria. Foremost was that we did not want to add to the current environmental strain that plastics placed on eco systems. Secondly, our source must be renewable which would create a closed loop in the life cycle of our products. Finally, our material must meet the high performance of industry demands in safety and durability. By using bio-resins we could confidently move forward with building blocks that exceeded those three fundamental requirements.

Our raw materials are made up of long molecular chains of the polymer polylactide. It is derived from naturally-occurring plant sugar and DOES NOT utilized petrol to produce. By eliminating the need for fossil fuel consumption, our products have a minimal carbon footprint without the restrictions of being dependent on a declining oil resource. Bio-resins also enjoy the additional benefits of significantly using less energy in production as opposed to plastics while at the same time reducing greenhouse gases

Furthermore, the end life of bio-resins carry with them greater options than polypropylene without negatively impact the environment.

ECO Profile

Eco Profiles determine the environmental impact of a product throughout its production phase. This is quantified by analyzing all of the inputs and outputs from the manufacturing process from field to the factory exit gate.

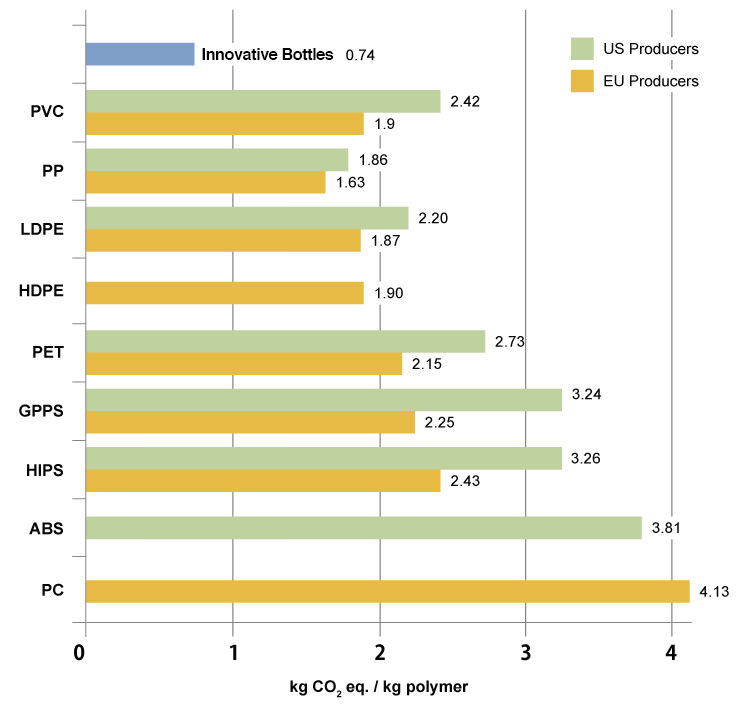

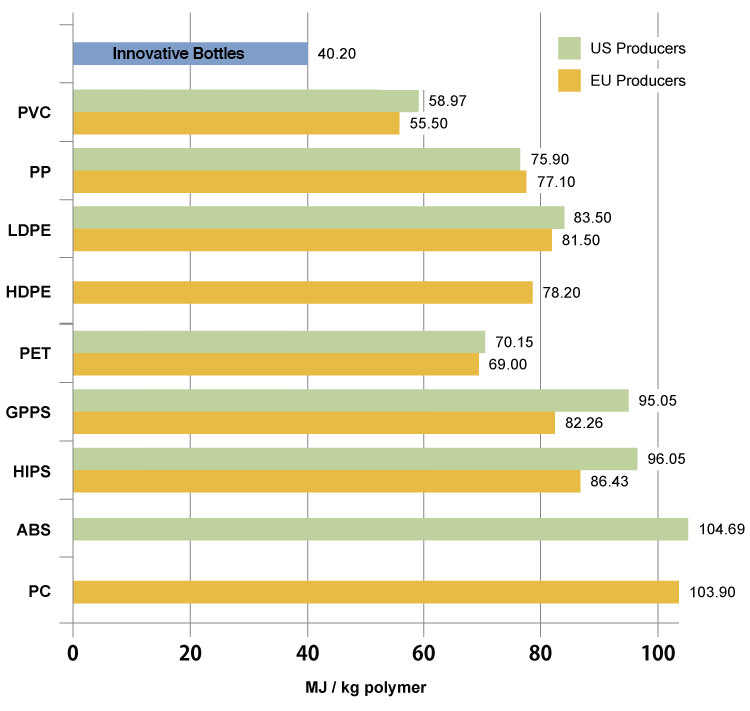

Two key indicators in a product’s environmental footprint are greenhouse gases (GHG’s) and non-renewable energy use. Measuring these two impacts and comparing the data against conventional polymers gives us a clear indicator of a product’s impact to the environment:

Comparing Greenhouse Imissions:

Comparing Non-Renewable Energy Use:

Certifications

The Certification for our Products and Technology meet:

- US PHARMACOPPEIA

- FDA well closed container USP 671

- USDA BioPreferred

- ASTM 6400 – BPI

- Consumer Product Safety Act 15U.S.C.s 2063(g)

- Poison Prevention Act

- Consumer Products Safety Commission for Child Resistant packaging

Our Products are also compliant with:

- Municipal & Industrial Composting

- Biobased Content ASTM 6866-5

- Chemical Control Law Compliance

- Food Packaging Materials and Food Contact Notification 178

- European Commission 1935/2004 EEC and Commission Directive 2007/72/EC